Sauce Pouch Packaging Machine Application

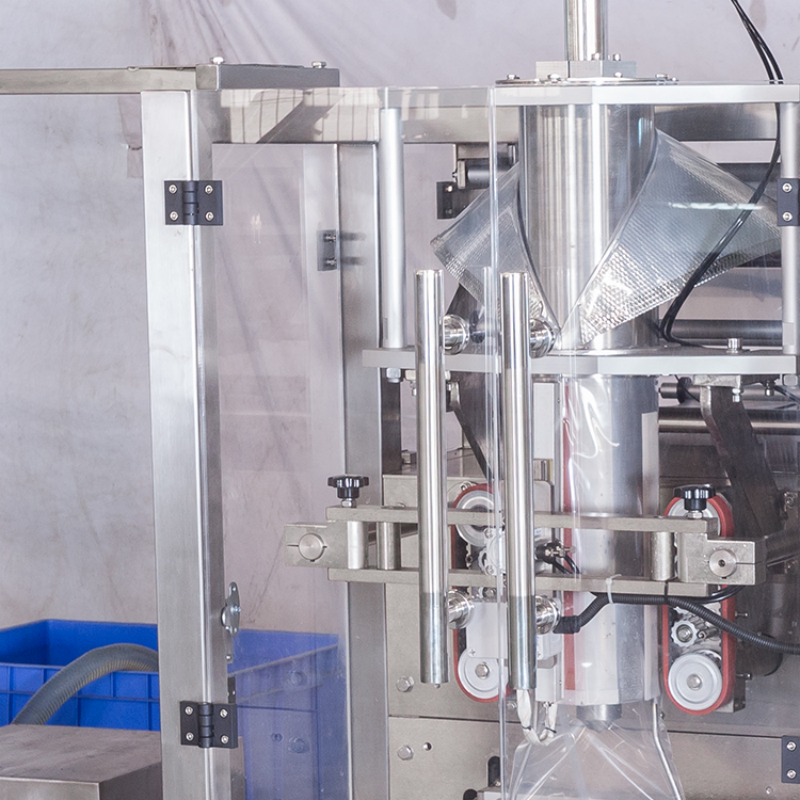

1.TT-420A/520A/720A Vertical Granule packing machinery is our company's introduction of foreign advanced technology, and is improved and the production of a kind of high quality, high-performance automatic packaging machine, complete automatic feeding, measuring,bag-making, deviation, filling, sealing, date printing and finished product output and a series of automatic functions.

2. The machine adopts a high-precision servo film transport system, and PLC program control, developed a touchable human-machine interface of advanced automatic positioning, photoelectric tracking, digital temperature control, etc.

3. Operation is more simple, and perfect. It is the first choice of the food packaging industry to improve production efficiency, reduce labor intensity, and improve the grade of packaging equipment.

4. Packaging material can be PE/polyethylene, PE/aluminum plating, pet/PE, pp, and other heat-sealing packaging materials, etc.

5. It completes the whole procedure of filling, measuring, bagging, date printing, charging(exhausting), and product out-putting automatically.

6. High precision, and high efficiency without crashing the materials.

| Main Machine Specification |

| Model | TT-420 | TT-520 | TT-720 |

| Film width | max 420mm | max 520mm | max 720mm |

| Bag length | max 300mm | max 400mm | max 500mm |

| Bag width | 60-200mm | 80-250mm | 180-350mm |

| Packaging Rate | 5-60bags/min | 5-60bags/min | 5-50bags/min |

| Measurement Range | 150-1500ml | 2000ml | 4000ml |

| Film Thickness | 0.04-0.08mm | 0.04-0.12mm | 0.04-0.12mm |

| Power | 220V 50/60Hz 2KW | 220V 50/60Hz 3KW | 220V 50/60Hz 4KW |

| Machine Size | (L)1217*(W)1015*(H)1343mm | (L)1488*(W)1080*(H)1490mm | (L)1780*(W)1350*(H)2050mm |

| Machine Quality | About 650KG | About 680KG | About750KG |

| Optional device | Date coder, Hole punching device (Pinhole, Round hole, butterfly hole), Linking bag control device, Airfilling device, and Air exhaust device. Tear notch device, Nitrogen inflation device, Gusset bag |