which machine is used for packing

Which machine is used for packing?

April 11, 2023

Before getting into the main topic, let me give you an overview of the trends in the development of packaging machines,Packaging machines are automated equipment used for product packaging and are widely used in multiple industries, such as food, pharmaceuticals, cosmetics, and daily necessities. With the continuous advancement of technology and changes in market demand, the trends in the development of packaging machines are also constantly evolving.with the advancement of automation technology, packaging machines are becoming more automated,according to market research data, the global market size of automated packaging machines is expected to reach $21.2 billion by 2023, with a projected CAGR of 6.7%.

Multi-functionality and flexibility: Modern packaging machines are increasingly focusing on multi-functionality and flexibility to adapt to rapidly changing market demands. For example, some packaging machines can package multiple types of products, thereby reducing the time and cost of equipment replacement and adjustments.According to market research data, the market for multi-functional and flexible packaging machines is expected to grow at a CAGR of 7.8% by 2023.

Trend towards intelligence and digitization: The application of intelligent and digital technologies in packaging machines is becoming more prevalent

Let people operate more simple and fast, greatly improve the efficiency For example, packaging machines utilizing artificial intelligence (AI) and machine learning can achieve intelligent optimization and adjustments, thereby improving production efficiency and product quality. Digital technologies also enable real-time monitoring and remote management of production data, thereby enhancing the level of fine-grained production management. According to market research data, the global market for smart packaging machines is expected to grow at a CAGR of 15.3% by 2023.

Therefore, the trend of the future, intelligent machines will gradually replace manual labor, packaging machine industry is also the outbreak period, there is a lot of space in the future

How to choose the right packaging machine?

To choose a packaging machine that is suitable for your needs, you need to consider several factors, including your production requirements, product nature, budget, space limitations, and future expansion plans.

1. Determine production requirements: First, you need to clarify your production requirements, including estimated output, packaging speed, and packaging specifications, etc. This will help you choose the type of packaging machine that is suitable for your production needs, such as automatic packaging machine, semi-automatic packaging machine, or manual packaging machine.I suggest choosing fully automatic is better, because fully automatic is more efficient than semi-automatic and reduces the cost—— →China TenToo ← Here is China Tengtu packaging machine supplier, 15 years of brand, export to more than 60 countries, 2 years of warranty their machines are fully automatic

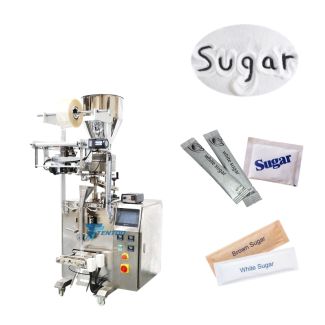

2. Determine your product category,Products are generally divided into granular powder and liquid, different products correspond to different types of packaging machines,You also need the estimated yield, packing speed, packing specifications, etc,If you buy automatic packing machine, you can control the packing speed, or the weight, so you don't need to worry, that's why I suggest you buy automatic。If you need to pack candy in a small bag and it doesn't have any requirements for appearance, I suggest you go small machine TT380,as following picture shows video presentation.

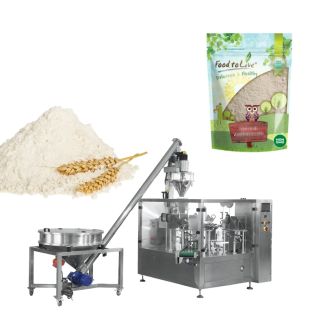

If you have high requirements for packing bags and large aesthetic size, I suggest you choose a large packing machine,High-end products all need a nice bag, don't they? You need to catch the eye of the consumer,you can choose TT-420A/520A/720A.

Below is the packaging display, we can choose our favorite bag style, or we can ask the seller to customize bags for ourselves.

The advantages of the TT-420A, 520A, and 720A are as follows。

1.Granule packing machinery is our company introduction of foreign advanced technology, and is improved and the production of a kind of high quality,high performance automatic packaging machine, complete automatic feeding,measuring,bag-making,deviation,filling,sealing,date printing and finished product output and a series of automatic functions.

2.The machine adopts high precision servo film transport system, PLC program control, developed touchable human-machine interface of advanced automatic positioning, photoelectric tracking,digital temperature control,etc.

3.Operation is more simple,perfect.It is the first choice of food packaging industry to improve the production efficiency,reduce labor intensity, improve the grade of packaging equipment.

4.Packaging material can be PE/polyethylene,PE/aluminum plating, pet/PE, pp,and other heat-sealing packaging materials, etc.

5.It completes the whole procedure of filling,measuring,bagging,date printing,charging(exhausting),product out-putting automatically.

6.High precision, high efficiency without crash the materials.

Consider space limitations: Packaging machines usually require a certain installation space, and you need to consider whether your production site has enough space to accommodate the packaging machine. Measure the dimensions of your production site to ensure that the selected packaging machine fits your space limitations.

Consider future expansion plans: If you plan to increase production scale in the future, you need to consider the scalability of the packaging machine. Some packaging machines can be upgraded or have accessories added to adapt to future production needs. Make sure the selected packaging machine has sufficient scalability for future expansion.

Understand the supplier and after-sales service: Choose a reliable supplier of packaging machines and understand their after-sales service policy and technical support. Packaging machines usually require maintenance and upkeep, and you need to ensure that the supplier can provide timely technical support and repair services to ensure the normal operation of the packaging machine。Don't be careful, most of the machine packaging programs on the market can be updated to make them more suitable for your production。

Refer to customer reviews and case studies: Review customer reviews and case studies to understand their feedback and usage of the packaging machine, in order to better understand the performance and reliability of the packaging machine.——TenToo packing machine Received the praise of customers from all countries

By carefully considering the above factors and comparing with multiple suppliers, you can make an informed decision in choosing a packaging machine that is suitable for your needs.

Summarize:TT380 shortcoming:The packing volume is small and the packing bag requirements are low advantage:Cheap price and small footprint, easy to move

TT-420A/520A/720A advantage :Packaging volume is large, can control 1-5KG and A variety of popular bag styles are available shortcoming:high price and cover a huge area

Powder packaging machine and liquid packaging machine selection method is the same as particle,Buyers need to understand their needs in order to find their own packaging machine.

some products will require special packaging machines, so you need to consult the seller in advance to inform you of your requirements.

There are several ways to assess the quality of a packaging machine. The following are some indicators that may help you evaluate the quality of a packaging machine:

1:Manufacturer reputation and credibility: The reputation and credibility of the packaging machine manufacturer are important indicators of quality. Understanding the manufacturer's history, experience, qualifications, and customer reviews can help you assess the quality level of their products,you can also ask if the business has ever exported to your own country.

2:Material and processing technology: The materials and processing technology of a packaging machine directly impact its quality. Check the machine's structural design, welding process, quality of components, etc., to see if they meet standards and if advanced technology and processes are used,support connection point is firm.

3:Performance and stability of the packaging machine: The performance and stability of a packaging machine are key factors in assessing its quality. Understand the machine's performance parameters such as packaging speed, packaging size range, packaging effect, etc., and observe its stability and reliability in actual operation.ask the seller to give the machine you bought a test run, check the size of the packaged product, weight.

4:Safety and compliance: A packaging machine should comply with relevant safety standards and regulations, such as CE certification. Check whether the machine has necessary safety measures, such as safety doors, emergency stop buttons, etc., and confirm if it complies with local regulations and standards.

5:After-sales service and warranty policy: Understand the manufacturer's after-sales service and warranty policy, including whether they provide timely technical support, spare parts supply, training, etc. A reputable packaging machine manufacturer should offer comprehensive after-sales service and warranty policy.

Okay, it's getting late, I'm going to go to bed, if you have any questions this is my YouTube account——https://www.youtube.com/channel/UCJthXys5r2QT11--KeaUFMA it's got videos on packaging machines,If you have any questions about the packaging machine, please leave a message to me, and I will reply to you in one working day. Next article: The most common packaging machine failures and solution